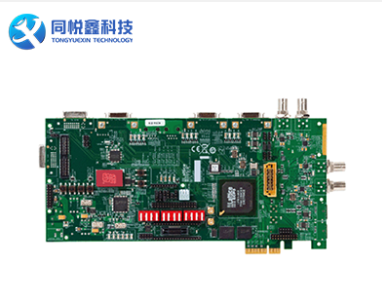

Before discussing the topic of "What is SMT surface mount?", we need to know that we are currently in an era of rapid development of electronic information. Nowadays, electronic technology is advancing at an unimaginable speed, which has brought about a very grand range of application scenarios for people. It also greatly facilitates the daily life of ordinary people. We can see some circuit boards covered with electronic components on the internet or in reality, and one of the basic operations in manufacturing circuit boards is SMT mounting.

SMT expresses the meaning of surface mount technology, which is the basic process technology for electronic assembly and the foundation of electronic product manufacturing. So what are the basic processes of electronic manufacturing?

SMT is mainly composed of several basic manufacturing processes such as dispensing, mounting, soldering, and testing. The entire process of SMT mounting revolves around these basic techniques:

The first thing that needs to be done is screen printing and glue dispensing process: its function is to leak solder paste or patch adhesive onto the basic solder pads on the PCB, mark them with solder paste, and then drip glue onto the fixed positions marked on the PCB board; The next process that needs to be carried out is mounting: this process is to fix and mount the specific electronic components on the fixed position of the dropper based on the previous step. The next step is a crucial step in the entire SMT surface mount process - curing and soldering: melting the surface mount adhesive to firmly adhere the components to the circuit board, and then melting the solder paste used for marking to secure the components more securely.

Another step is the cleaning and quality inspection of the entire electronic board: after the electronic board is mounted, it is necessary to clean and remove harmful substances such as welding agents that remain in the manufacturing process, and to inspect the quality of the circuit board to remove any products that do not meet the standards for repair.

The above is a simple process flow for SMT surface mount processing. In actual production, there may be more complex mounting processes such as double-sided assembly, single-sided mixing, and double-sided mixing. Nowadays, electronic products are developing towards personalization and miniaturization, with increasingly high requirements for processing accuracy. Therefore, the process requirements for surface mount will also be higher.